Chemical and Coal Chemical Industry

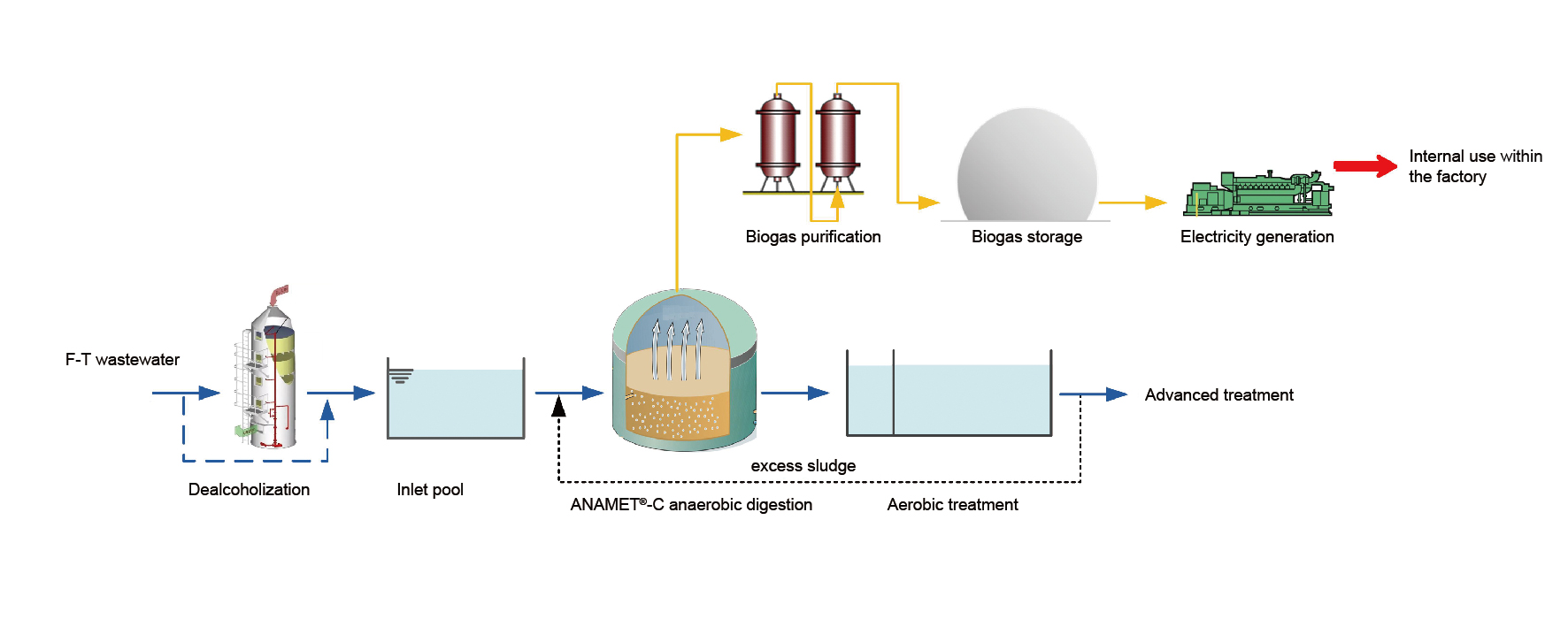

ANAMET®-C is a highly efficient anaerobic process developed by Purac based on ANAMET ® process, specifically for the treatment of high COD and low pH acidic wastewater, especially suitable for coal indirect liquefaction Fischer Tropsch synthesis wastewater and acrylic acid wastewater. This process has been experimentally proven in Yitai Coal Chemical Project.

Compared with the current acidic wastewater treatment processes in the industry, ANAMET ® - C has the following advantages:

1. Stable and reliable operation.

2. Strong impact resistance. For anaerobic influent with an infinite pH value (actual operating condition pH>2 in the industry), petroleum<100mg/L, and COD infinite value (actual operating condition COD<102900mg/L in the industry).

3. High COD removal rate (94-99%) and stable effluent quality. The effluent from the subsequent aerobic system is more likely to meet the standard, reducing the operating costs of the aerobic system.

4. Low cost of sludge disposal. Collaborative treatment with sewage can reduce costs by 35-50% and lower subsequent disposal expenses.

5. Anaerobic sludge has low cost. One time of vaccination, no need to add sludge afterwards.

6. The overall system has a high degree of automation and fewer operation and maintenance personnel.