DAF

Purac Dissolved Air Flotation technique is an effective and rapid method for separation of particles from water and wastewater, developed and refined since 1950s.

Advantages as follows:

- Guaranteed performance

- Low investment

- Compact design

- Short flocculation time, 5-10 minutes

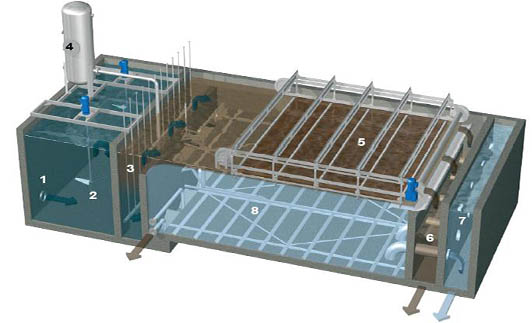

Water flowing into the DAF tank is injected with a high-pressure air/water solution, derived from recycling some 10% of the plant flow through an air/water saturation system. Regulation of pressure release valves causes the pressure of the recycled water to suddenly drop. This pressure change creates micro-bubbles that attached to the flocculated material and rapidly carry it to the surface, forming a stable floating sludge.

Surface sludge is removed by a chain-driven flight scraper into a trough from where it is transported to storage.